Reasons of mistracking of a conveyor belt can be widely distributed and it is hard to identify a reason. The mistracking of a conveyor belt normally has many reasons.

Each reason influences another reasons, so a determination of one reason can not always be possible. It is hard to find the problem when it always changes. To track a belt visit the “How to Track a Belt“.

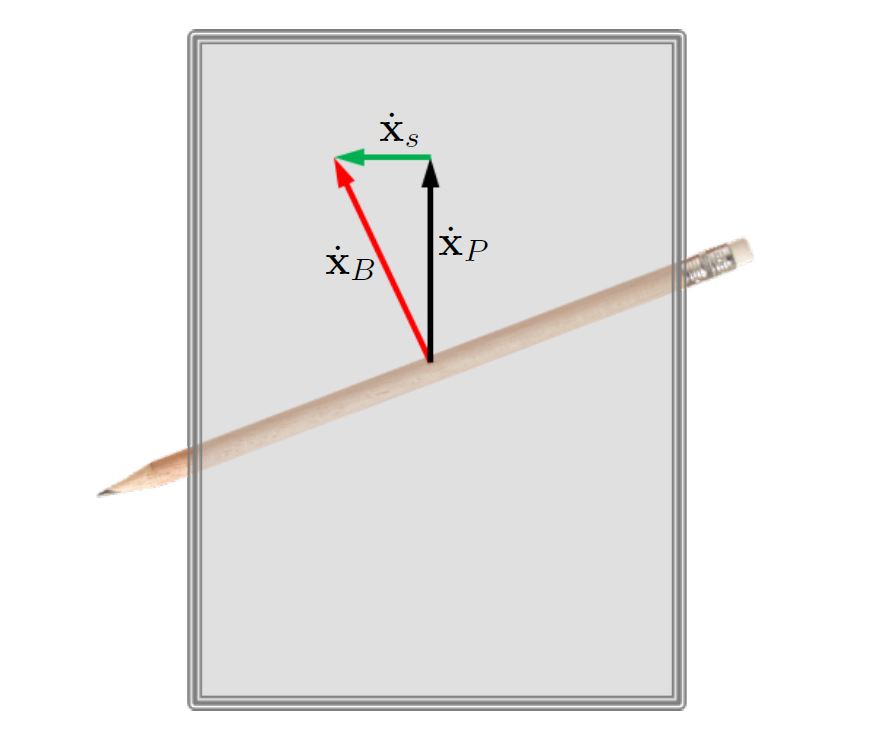

The mechanic is always related to an angle between the belt and the idler. A very simple model is shown in the book that gets pushed over a misaligned pencil which is not perpendicular to the edges of the book. The book is pushed forward but it is moving sideways in the same time, without slipping on top of the pencil. Now imagine a belt and an idler…

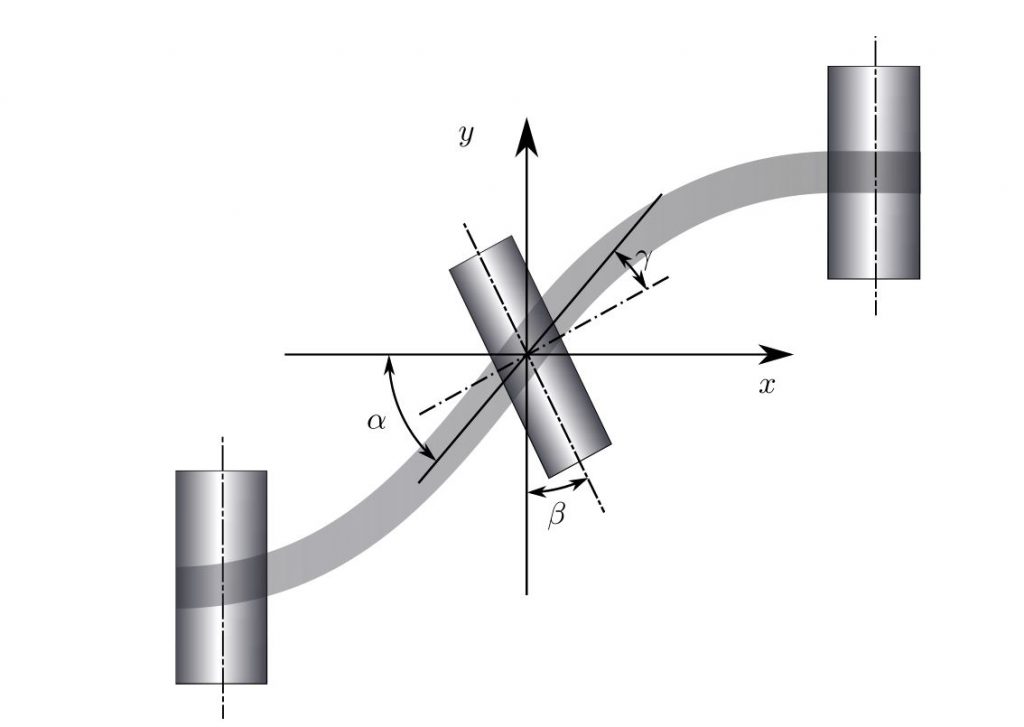

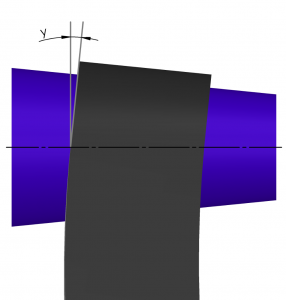

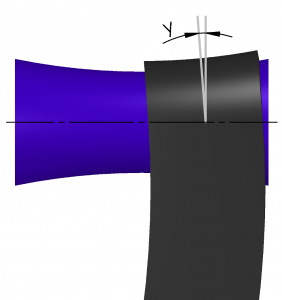

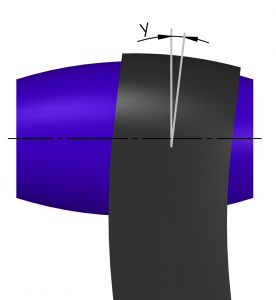

To make a conveyor belt run sideways either the belt has to be deformed (anlge alpha) or a idler or pulley has to be skewed (angle beta). Both lead a contact angle between the belt and the idler or pulley.

A reason why a belt does not track right, is always related to a deformation of the belt or a skewed idler station or pulley. The goal for tracking a conveyor belt must always be to find and eliminate the deformation or the tristed idler.

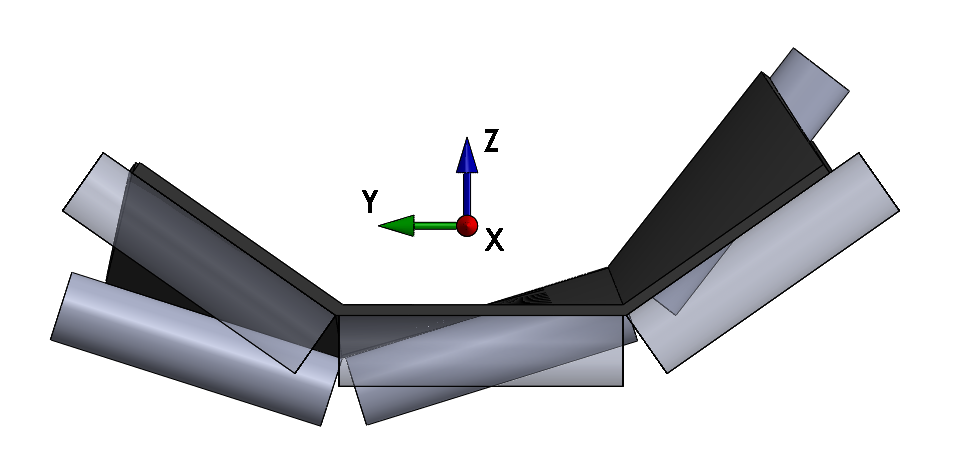

A rotation around the conveying axis will not result in direct belt mistracking. As shown, the belt will be twisted as well, which will cause mistracking. Because the entire mass of the belt and the bulk material tries to reach the lowest possible value of potential energy, the belt will move sideways. The centering effect by mass applies forces in the troughed belt, which deforms the belt between its contact points in sideways direction.

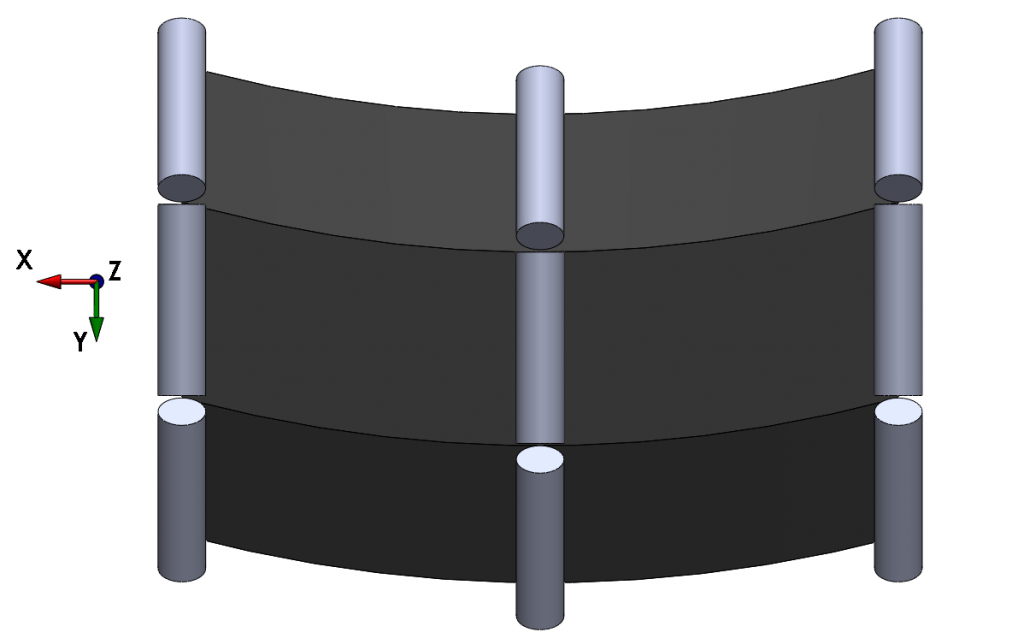

A rotational misalignment around the vertical axis is known as a skewed idler station. The skewed station in the figure will steer the belt in the normal direction of the idler. The sideways movement is directly proportional to the angle of skew, as long as the force acting on the belt is smaller than the maximum frictional force between the belt and idler. Otherwise the belt will slip above the idler. The occurring steering effect can be used as an output value in a controlled training idler.

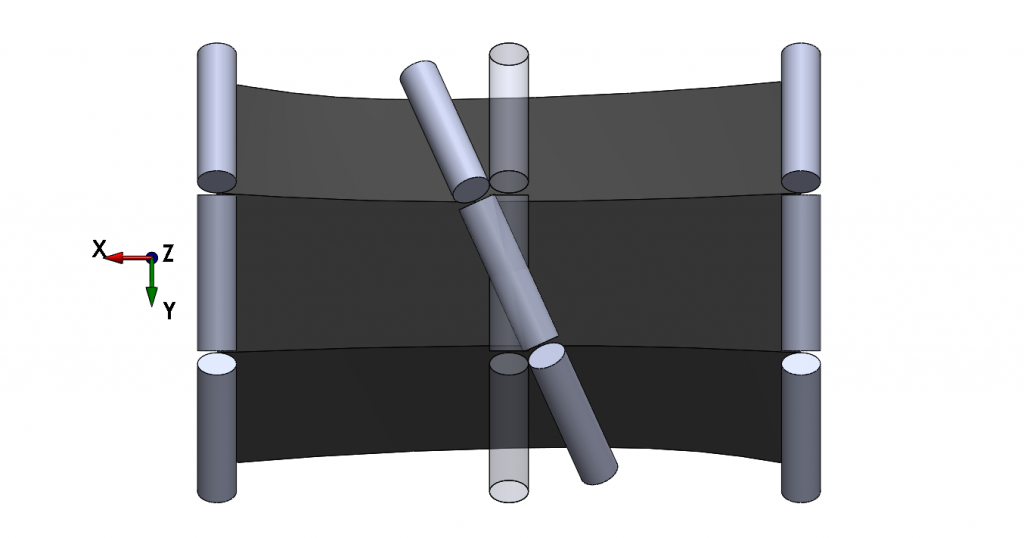

Obviously, the misalignment in vertical and conveying direction can be neglected because they will not lead to a deformation of the belt or an angle. A misalignment in sideways direction will shift the idler station relative to the belt centre line. Mistracking will occur as an effect of the self-alignment of the conveyor belt. The belt tries to follow the lowest points of the idler stations due to its self-centering behaviour caused by belt and bulk material mass.

For a single idler station the mechanics can be much more complex.

The off-centered load of bulk material to the belt can have two reasons. In the first case the material is loaded eccentric on a centred belt, due to wrong settings or a poor design of the transfer chute. The weight force of the eccentric bulk material results in a belt deflection which causes a sideways movement. A self-intensifying eccentric belt movement is given, if the belt is not centred before the transfer chute. The bulk material would be loaded eccentric on an already off-centred running belt.

The second case is the centered load on an eccentric running belt. This will not result in belt mistracking because the weight force keeps the belt stable in its off-centred position.

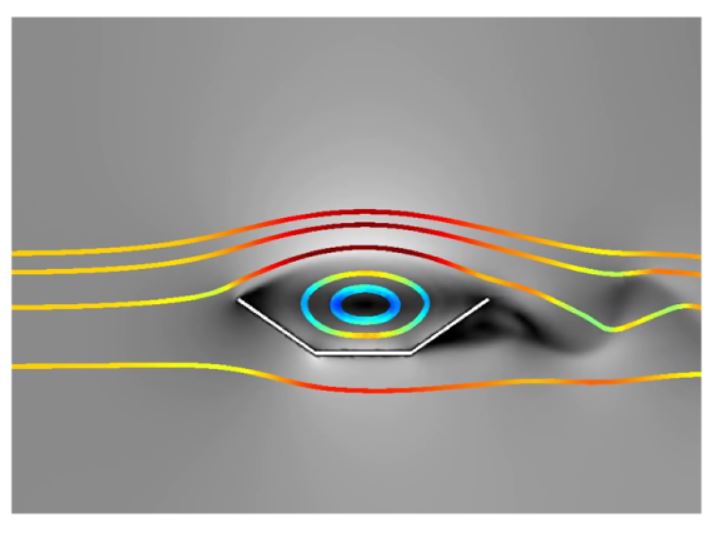

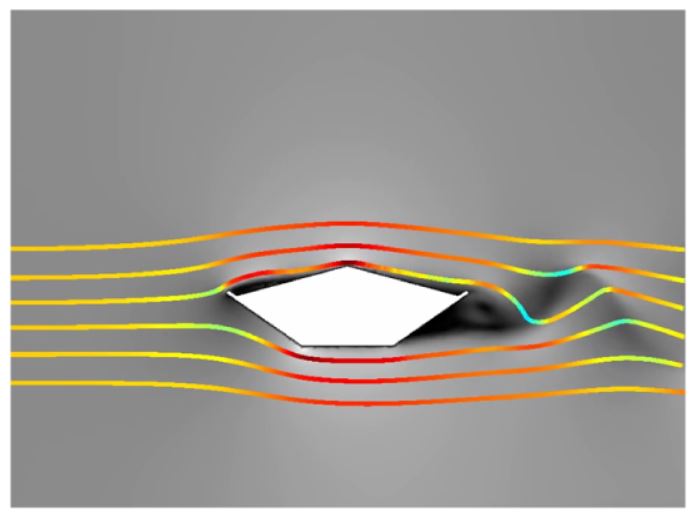

It can result in belt mistracking. Forces in the lateral direction act on the belt because of the air flow around the belt with high velocities. This can lead to mistracking if the forces are high enough to deflect the belt in its y-direction. With increasing wind velocity the belt can be blown from the conveyor idlers. Similar to other simulations a Computational Fluid Dynamics (CFD) simulation can be used for the analysis of the resulting forces. Another method could be the study of the wind forces in a wind tunnel. Those experiments are expensive and time-consuming, so the CFD simulation should be preferred.

If a scraper is not set up or choosen correctly, material build up can happen on the pulleys and idler. The build up leads to a change of the surface geometry.

The surface geometry can be crowned, conical, concave or indifferent. The change of surface geometry will always lead to unstable belt tracking.

For more information you can check under: Simulation of Beltmistracking on this ResearchGate publication.

Privacy Preference

Privacy Preference

We use cookies on our website. Some of them are essential, while others help us to improve this website and your experience.

Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.

Essential cookies enable basic functions and are necessary for the proper function of the website.

| Name | |

|---|---|

| Provider | Owner of this website |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

Marketing cookies are used by third-party advertisers or publishers to display personalized ads. They do this by tracking visitors across websites.

| Accept | |

|---|---|

| Name | |

| Provider | Google LLC |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Host(s) | |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

| Accept | |

|---|---|

| Name | |

| Provider | YouTube |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |